Food Safety Record Keeping Made Simple

Finally, GMP compliance without the complexity and high cost. Built for small food manufacturers who need reliable tracking without the enterprise-level overhead.

Simple and affordable.

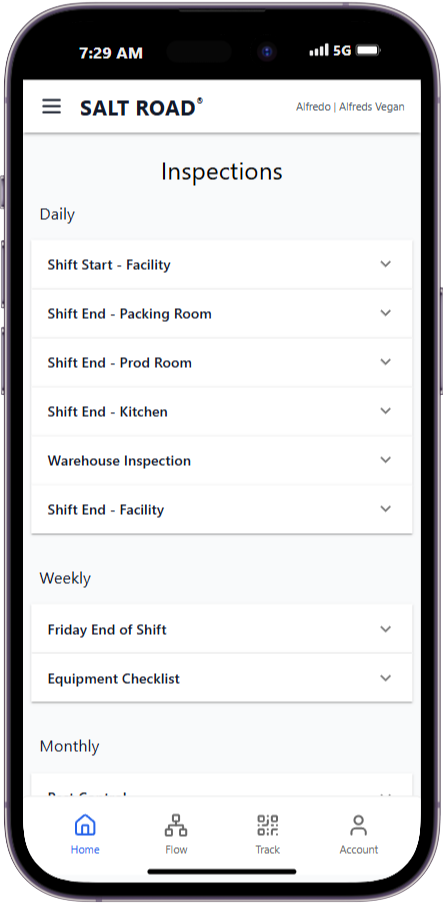

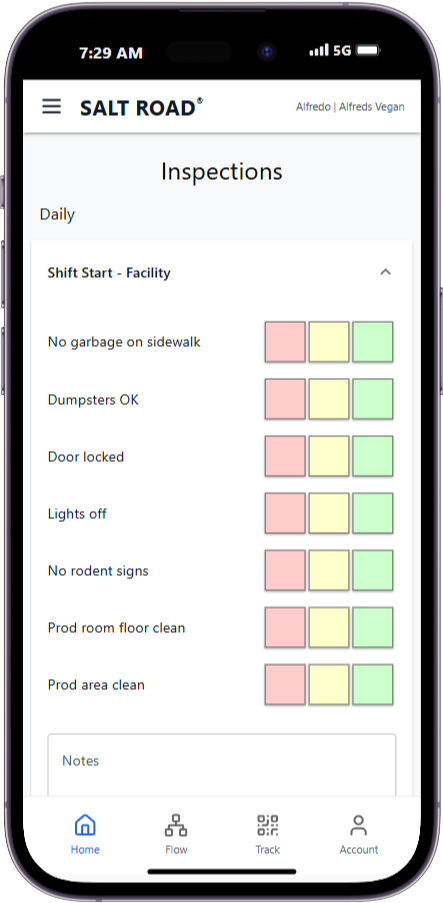

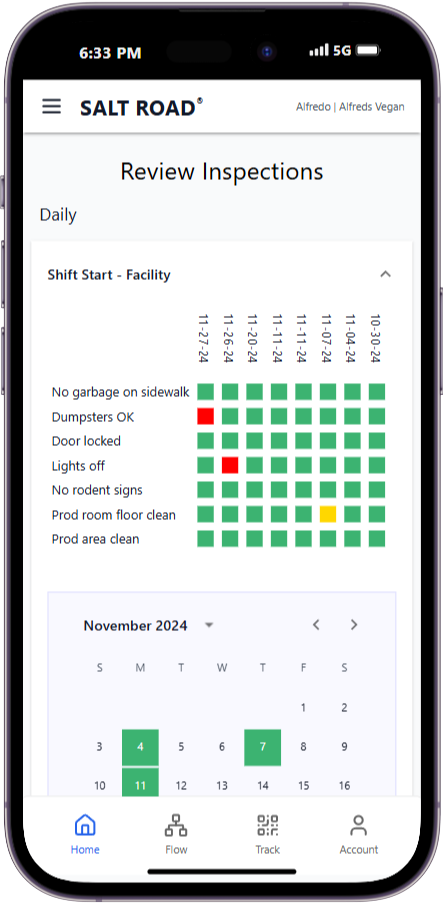

Smart Inspection Management

Create, perform, and review inspections in one place. Mobile-friendly design means you can do inspections right on the production floor. Automatic scheduling keeps you on track.

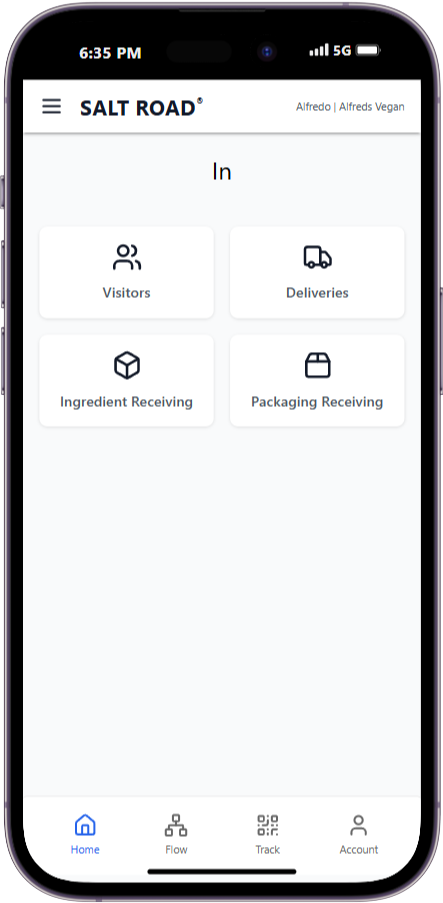

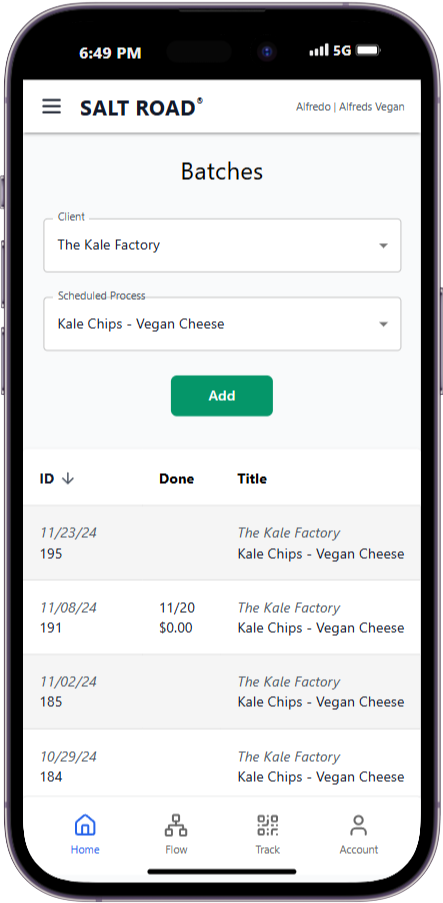

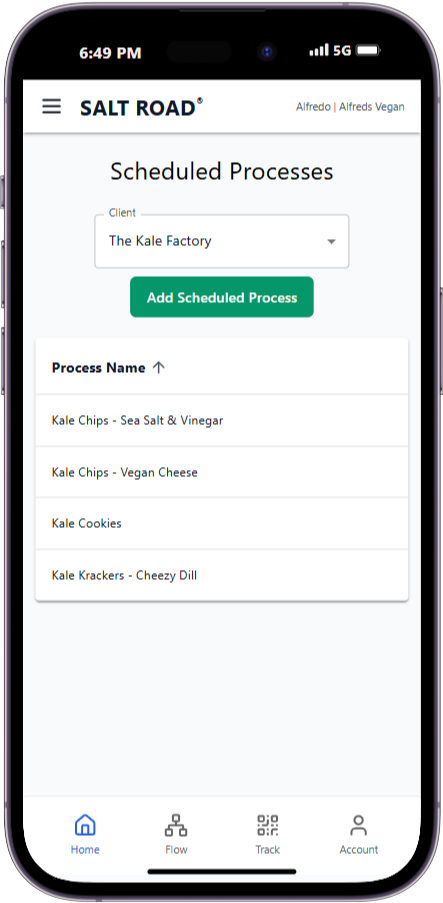

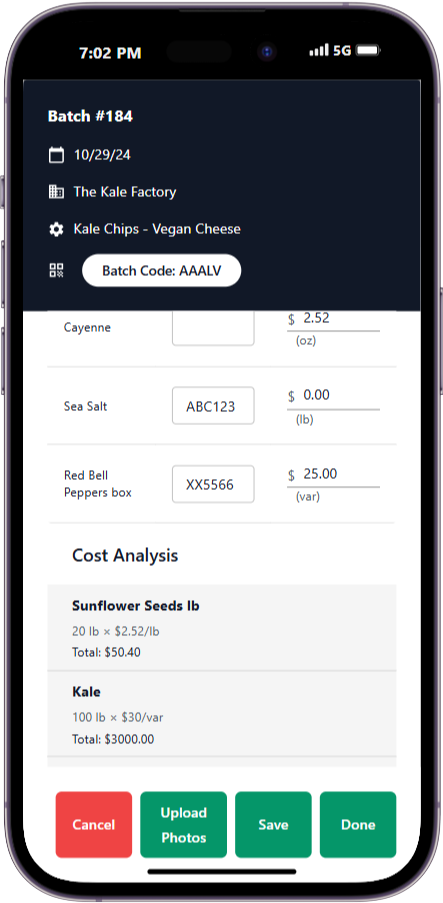

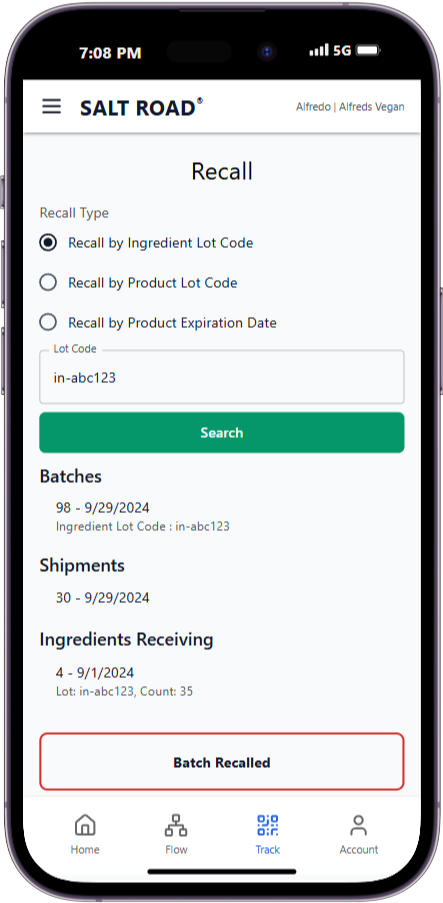

Practical Batch Tracking

Track your production from ingredients to finished products. Create scheduled processes, manage batches, and track lot codes without the paperwork headache. Full recall capability when you need it.

Real-Time Cost Tracking

Know your actual production costs. Track ingredient costs, monitor inventory levels, and see batch profitability at a glance. Make informed decisions with real data.

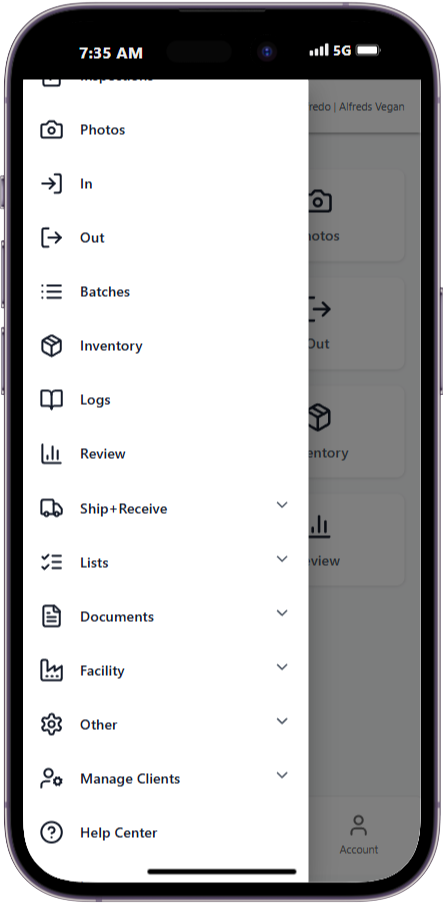

Complete Production Visibility

See your entire production flow in one view. Track inventory movement, monitor production status, and keep tabs on everything from receiving to shipping.

Production Flow Overview

See how all modules work together to streamline your production process. Click on any feature for a detailed description.

List"] N["Packaging

List"] O["Brands

List"] P["Products

List"] A["Ingredient

Suppliers"] B["Packaging

Suppliers"] C["Deliveries"] D["Ingredients

Receiving"] E["Packaging

Receiving"] F["Ingredients

Inventory"] G["Packaging

Inventory"] H["Batches"] I["Scheduled

Processes"] J["Product

Inventory"] K["Shipments"] L["Recalls"] M -.-> A N -.-> B O -.-> P P -.-> I A -.-> C B -.-> C C --> D C --> E D --> F E --> G F --> H G --> H I --> H H --> J J --> K K -.-> L %% Click definitions for desktop click M call callback("Ingredients List: Maintain your master list of ingredients with allergen information, supplier details, and specifications.") click N call callback("Packaging List: Track all packaging materials including specifications, suppliers, and minimum order quantities.") click O call callback("Brands List: Manage different brands and their associated products and specifications.") click P call callback("Products List: Catalog of finished products with full specifications, allergen info, and packaging requirements.") click A call callback("Ingredient Suppliers: Track approved suppliers, certifications, and purchasing information for ingredients.") click B call callback("Packaging Suppliers: Manage packaging vendor information, certifications, and order requirements.") click C call callback("Deliveries: Schedule and track incoming deliveries of ingredients and packaging materials.") click D call callback("Ingredients Receiving: Record and verify incoming ingredient deliveries, lot codes, and specifications.") click E call callback("Packaging Receiving: Process incoming packaging materials with quality checks and inventory updates.") click F call callback("Ingredients Inventory: Real-time tracking of ingredient stock levels, lot codes, and storage locations.") click G call callback("Packaging Inventory: Monitor packaging material inventory with lot tracking and minimum stock alerts.") click H call callback("Batches: Create and track production batches with full ingredient traceability and cost tracking.") click I call callback("Scheduled Processes: Define and manage your production processes and food safety parameters.") click J call callback("Product Inventory: Track finished product inventory with lot codes and storage locations.") click K call callback("Shipments: Manage outgoing shipments with lot code tracking and customer information.") click L call callback("Recalls: Initiate and manage product recalls with full lot code traceability.") classDef default fill:#4CAF50,stroke:#333,stroke-width:2px,color:white classDef list fill:#2196F3,stroke:#333,stroke-width:2px,color:white classDef purple fill:#9C27B0,stroke:#333,stroke-width:2px,color:white class M,N,A,B,O,P list class C,K purple

List"] N["Packaging

List"] O["Brands

List"] P["Products

List"] A["Ingredient

Suppliers"] B["Packaging

Suppliers"] C["Deliveries"] D["Ingredients

Receiving"] E["Packaging

Receiving"] F["Ingredients

Inventory"] G["Packaging

Inventory"] H["Batches"] I["Scheduled

Processes"] J["Product

Inventory"] K["Shipments"] L["Recalls"] M -.-> A N -.-> B O -.-> P P -.-> I A -.-> C B -.-> C C --> D C --> E D --> F E --> G F --> H G --> H I --> H H --> J J --> K K -.-> L %% Click definitions for mobile click M call callback("Ingredients List: Maintain your master list of ingredients with allergen information, supplier details, and specifications.") click N call callback("Packaging List: Track all packaging materials including specifications, suppliers, and minimum order quantities.") click O call callback("Brands List: Manage different brands and their associated products and specifications.") click P call callback("Products List: Catalog of finished products with full specifications, allergen info, and packaging requirements.") click A call callback("Ingredient Suppliers: Track approved suppliers, certifications, and purchasing information for ingredients.") click B call callback("Packaging Suppliers: Manage packaging vendor information, certifications, and order requirements.") click C call callback("Deliveries: Schedule and track incoming deliveries of ingredients and packaging materials.") click D call callback("Ingredients Receiving: Record and verify incoming ingredient deliveries, lot codes, and specifications.") click E call callback("Packaging Receiving: Process incoming packaging materials with quality checks and inventory updates.") click F call callback("Ingredients Inventory: Real-time tracking of ingredient stock levels, lot codes, and storage locations.") click G call callback("Packaging Inventory: Monitor packaging material inventory with lot tracking and minimum stock alerts.") click H call callback("Batches: Create and track production batches with full ingredient traceability and cost tracking.") click I call callback("Scheduled Processes: Define and manage your production processes and food safety parameters.") click J call callback("Product Inventory: Track finished product inventory with lot codes and storage locations.") click K call callback("Shipments: Manage outgoing shipments with lot code tracking and customer information.") click L call callback("Recalls: Initiate and manage product recalls with full lot code traceability.") classDef default fill:#4CAF50,stroke:#333,stroke-width:2px,color:white classDef list fill:#2196F3,stroke:#333,stroke-width:2px,color:white classDef purple fill:#9C27B0,stroke:#333,stroke-width:2px,color:white class M,N,A,B,O,P list class C,K purple

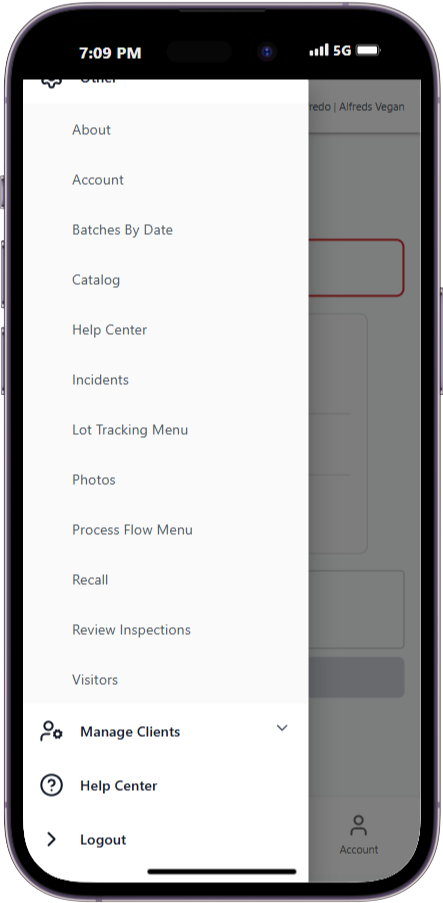

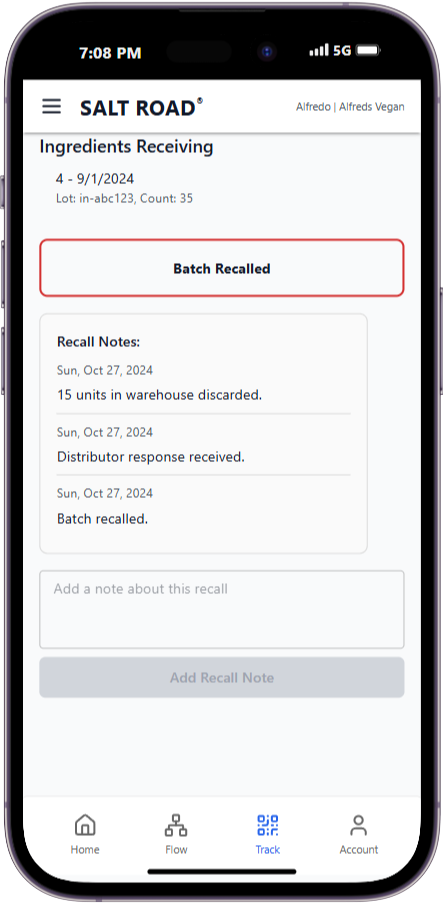

Recall Management

Fast, accurate recalls when you need them. Trace affected products, track recall progress, and document every step. Turn a crisis into a managed process.

Perfect for Co-Packers

Manage multiple clients and their products with ease. From production to invoicing, everything is organized by client.

Multi-Client Management

Keep each client's products, recipes, and specifications separate and organized. Switch between clients with a single click.

Automated Invoicing

Generate invoices directly from batch records. Track production costs and apply your markup automatically.

Client-Specific Inventory

Track ingredients, packaging, and finished products by client. Maintain separate storage locations and minimum stock levels.

Sales Tools Included

Create professional sales sheets and online catalogs for each client. Share product specifications and pricing easily.

Great for Food Safety Consultants

Help your clients maintain compliance and optimize their food safety programs. Track multiple facilities with comprehensive monitoring and documentation.

Multi-Client Compliance

Monitor food safety programs across multiple facilities. Track inspections, corrective actions, and documentation for each client separately.

Comprehensive Reporting

Generate detailed compliance reports and audit trails. Document corrective actions and track food safety improvements over time.

Batch and Recall Management

Help clients track production batches, manage recalls, and maintain complete traceability records. Monitor critical control points and verify compliance.

Program Implementation

Set up customized food safety programs for each client. Create templates for inspections, monitoring procedures, and corrective actions.

Easy Document Management

Keep all your certifications, compliance documents, and important records in one secure place. No workflows or complex features, just a no-frills collection of the documents you need.

Certification Tracking

Manage Kosher, Organic, Non-GMO, and other certification documents. Track renewal dates, inspection schedules, and compliance requirements. Get automatic notifications before certifications expire.

Employee Documentation

Store and monitor Food Handler certifications, training records, and employee qualifications. Track expiration dates and maintain up-to-date records for all staff members.

Vendor Management

Keep track of pest control reports, maintenance contracts, and supplier agreements. Store vendor certifications and insurance documents with automatic renewal reminders.

Audit Ready

Maintain organized, easily accessible documentation for regulatory inspections and third-party audits. Generate complete document packages for certification renewals or compliance reviews.

Get Started Today

Ready to simplify your food production management? Tell us about your business and we'll show you how Salt Road GMP can help.

90 day free trial available for qualifying companies.